Advanced hybrid technology punching-shearing center

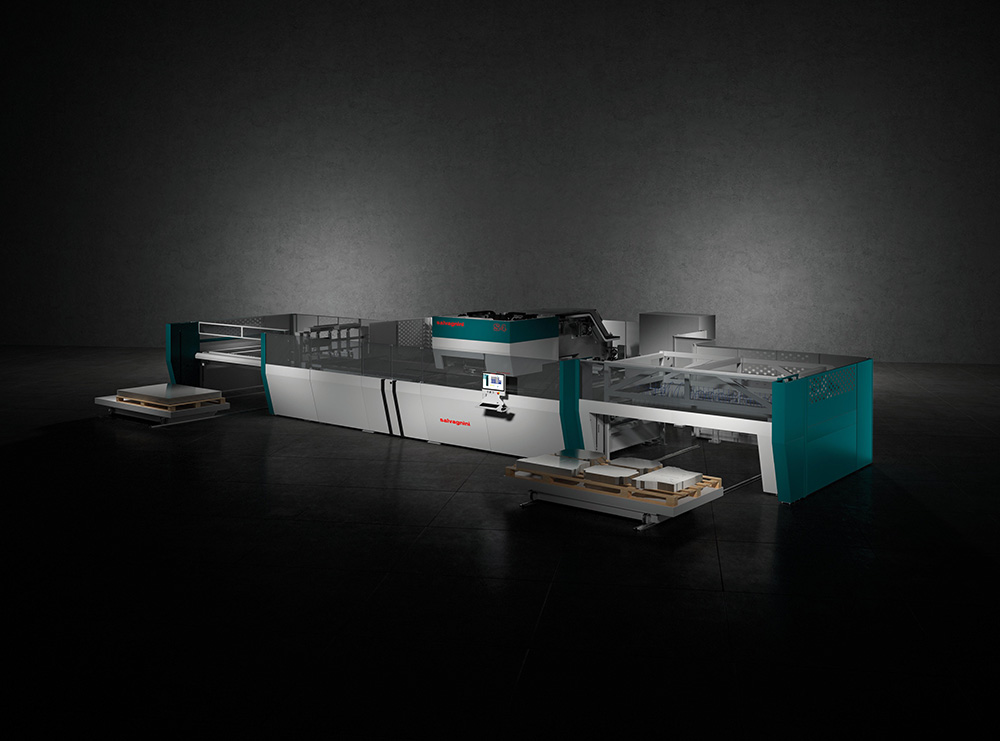

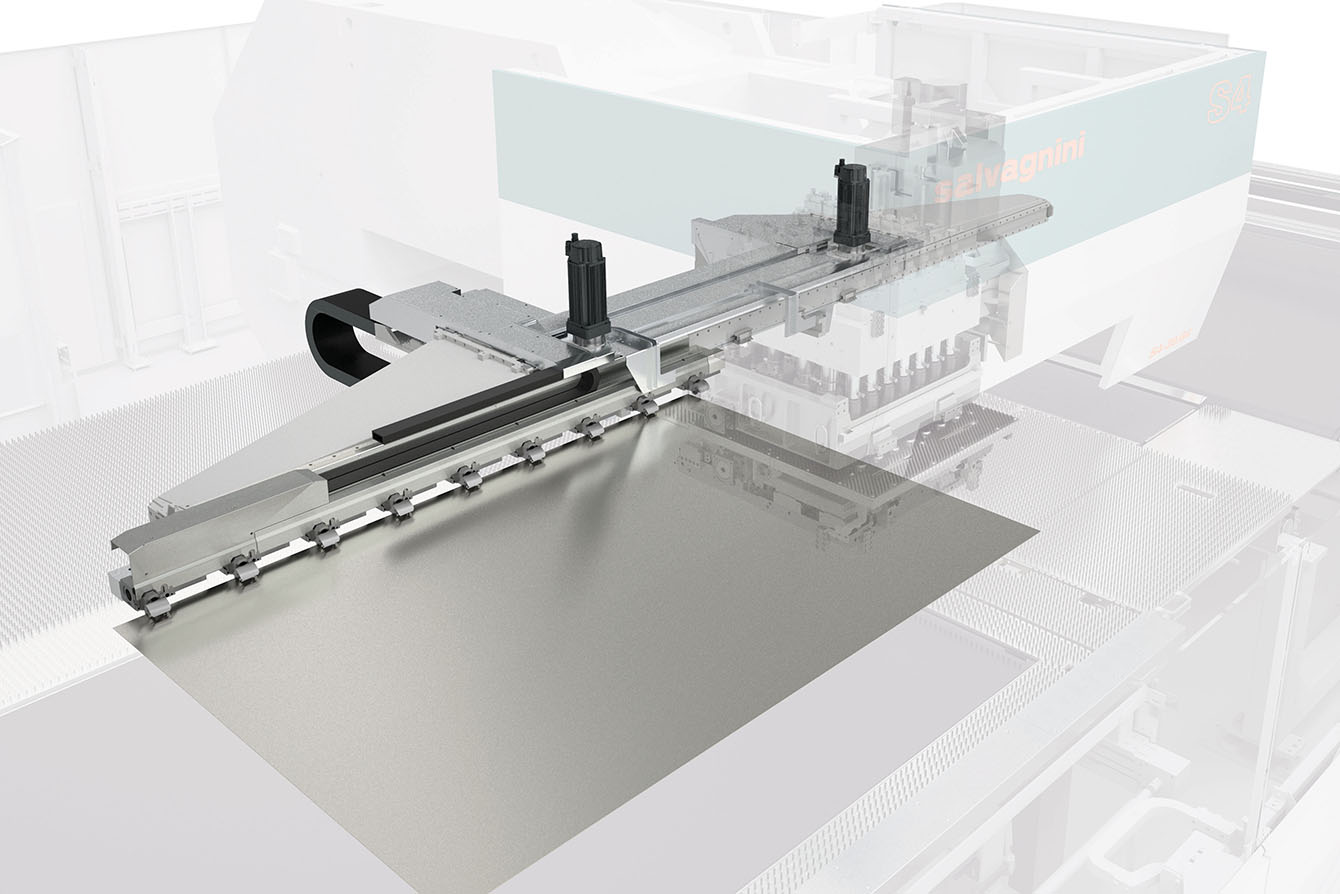

Introducing the Salvagnini S4.G4: a hybrid punching-shearing machine offering unmatched productivity, efficiency, and flexibility.

Performance greater than the sum of its parts

Designed for businesses seeking unparalleled productivity, flexibility, and efficiency, the S4.G4 integrates punching, forming, and part separation in one seamless operation. Backed by over 45 years of innovation, the S4.G4 is ideal for companies in sectors ranging from HVAC to metal furniture, ensuring consistent, high-quality output while drastically reducing lead times.

Product overview

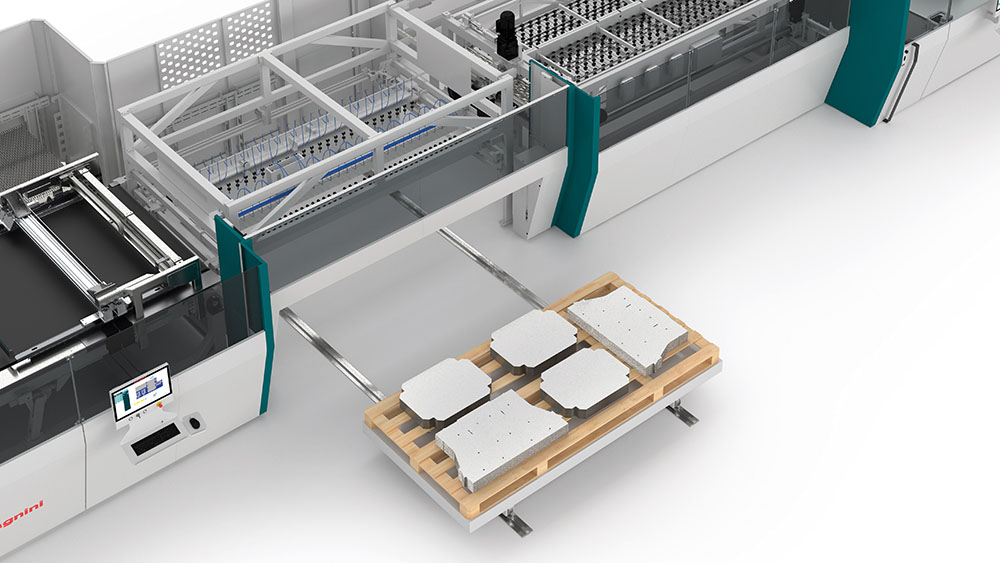

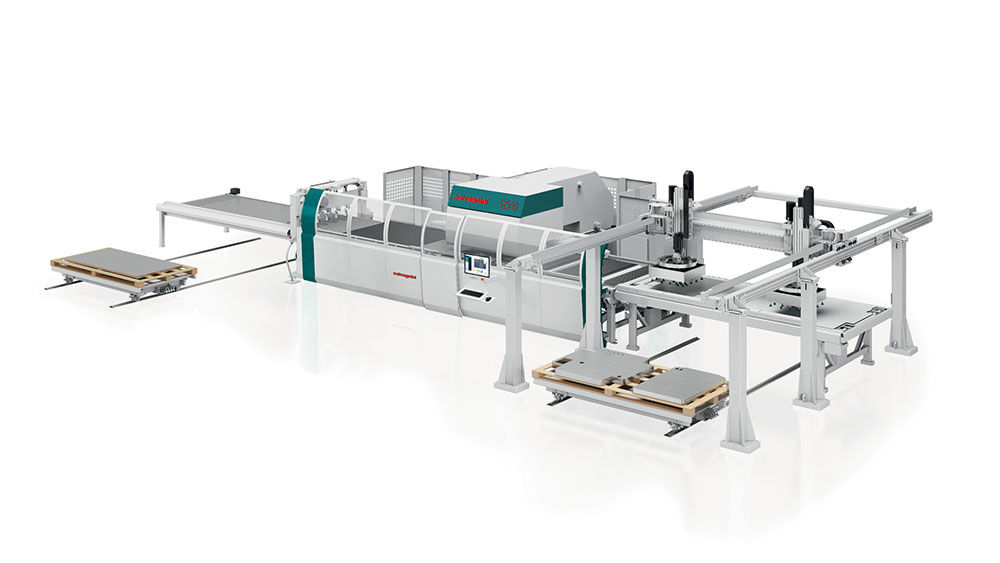

The S4.G4 punching-shearing center maximizes process efficiency: all the loading, punching, forming, separation and unloading operations are automatic, done by a single system that eliminates semi-finished parts, does not require manual intervention and assures extreme repeatability.

The integrated adaptive technologies make the system intelligent and able to automatically adapt to variations, eliminating waste and corrections, while guaranteeing high machining quality and process reliability:

- the advanced hybrid actuator solution progressively delivers energy, modulating consumption according to the machining to perform, the material to punch and the required force;

- the centering control system measures the incoming sheet and adapts the program to the actual dimensions measured, if necessary;

- the manipulator changes its dynamics according to the size and weight of the sheet, controlling the programmable opening of the pincers according to the percentage of sheet machined;

- an automatic system checks the thermal expansion of the manipulator’s axes and compensates any variations, guaranteeing extreme positioning precision;

- the shear automatically records the clearance and, depending on the thickness and the material, modulates the required force in-cycle.

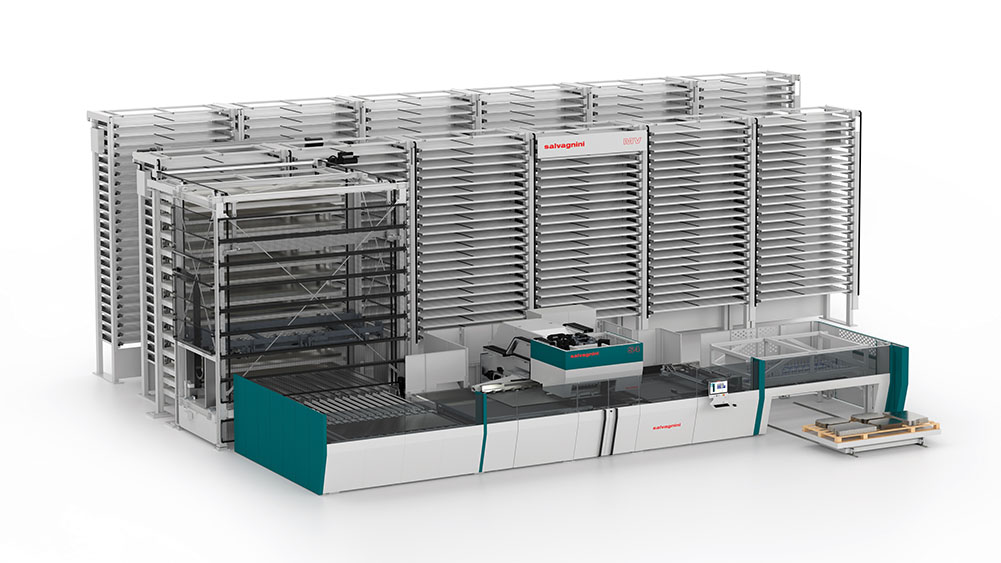

Storage and automatic loading/unloading devices increase the autonomy of the system, regaining efficiency both in individual processing steps and throughout the production process. The wide range meets practically any layout or configuration requirements, adapting to the most diverse production strategies.

Multi-press head: tools always available

The multi-press head has a die structure housing up to 117 thick turret tools in stations B, C and D, the latter with a maximum force of 30 tons, all with a 9 mm sharpening margin and all available on the area of the largest sheet. The head can also mount lower cylinders and, on station D, Multitool forming tools. Each tool is actuated individually and is always available.

High-performance tools

The thick turret tools recommended for S4.G4 are those designed and manufactured by Matrix Tools. On the market for over 40 years, the company covers the whole production chain manufacturing standard, parametric and tailored solutions to meet specific needs, always guaranteeing the highest standards of quality and reliability.

TOOLS

TOOLS is the new Salvagnini software module for the graphic management of the punching tool database in punching-shearing centers and punch-laser combi machine. It defines the tools interactively and graphically, simplifying the insertion of punches of various shapes, creating set-ups for punching heads, and managing the behavior of each punch and die when associated with different materials and thicknesses.

Tapping? No problem

An optional electrical tapping unit, which can house up to 6 different tools, can be installed to the side of the operating head. It does not steal any room from the tools as it is positioned outside the head.

Manipulator: accurate referencing and fast scrap-free processing

The manipulator centers the sheet when machining begins. It has a maximum stroke of 3030 mm which allows sheets of up to 3048 mm to be machined without regripping, and has 9 pneumatic pincers with independent opening and closing, extending the possibility of machining nests without any holding scrap and reducing scrap. It has a patented hand-over system that modulates the dynamics according to the weight of the sheet metal being processed.

Integrated shear

The shear is composed of two 500 mm blades, which are independent and orthogonal to each other, equipped with blankholders, for cutting any length. Installed next to the multi-press head, the shear is a distinctive solution and unique on the market, ensuring optimal, constant alignment and superior machining quality.

Automation plays an increasingly important role: it reduces the risk of loading and unloading becoming bottlenecks, and can help to reduce the impact of labor costs. The Salvagnini loading/unloading and sorting connections satisfy all automation requirements: from stand-alone operation, to integration in flexible cells or in automatic lights-out factories.

Intelligent system, constant quality

Practically everything you ever wanted to know about the S4.G4 punching-shearing center, satisfactorily explained.

Today companies have to cope with many challenges in order to remain competitive in a continuously developing market. These challenges include:

- The need to automate information distribution, in order to create a lean, error-proof production environment, by integrating company ERP/MRP systems with process software for production management.

- The growing need to increase the autonomy and efficiency of production systems by automating loading, unloading and sorting operations.

- Finally, to prevent programming from becoming a bottleneck for production, the aim of implementing simple and quick office software solutions, able to make procedures leaner and improve overall efficiency.

For Salvagnini, punching is always a combined process of forming and separating parts, with the separation done either by shear or by laser. The Salvagnini S4.G4 punching-shearing machine is the ideal solution for businesses looking for productivity, flexibility, reactivity and efficiency. The S4.G4 performs all the part punching, forming and separation operations by subtraction, destroying the skeleton to ensure that the parts flow progressively downstream: this eliminates the need for regripping and rapidly feeds the next production step. Part separation integrates the punching machine in a modern and efficient production flow, able to feed the workstations downstream, such as the panel bender.

Part geometries, increasingly small batch sizes, cutting quality and expected productivity are all factors that make the investment in an S4.G4 more attractive than that in a traditional punching machine. High productivity is guaranteed because the S4.G4 is a single work center, able to automatically produce finished parts without the need for re-machining and/or retooling. It is the winning solution in production contexts in which lead times have to be minimized, because the integration of forming and separation processes drastically reduces throughput times. The S4.G4 is the ideal solution in sectors requiring parametric jobs: more flexible than a laser, it drastically simplifies programming and reduces overall process times, from product design to production.

The S4.G4 natively integrates the punching and separation operations and automatically manages the feeding, sorting and unloading cycles which, when possible, are performed in masked time. With the patented multi-press head, the tools are always available for nesting and multiple jobs. The proprietary Punch&Cut algorithm optimizes the integrated shearing cuts for separating the single parts of the workpiece in a fast, flexible and automatic sequence with no waiting times.

With conventional punching, productivity and flexibility depend on the number of tool changes in-cycle and the times for moving the sheet underneath the turret or single punch, and are influenced by the time required for the separation operations downstream. The S4.G4, on the other hand, natively combines productivity and flexibility. Helping to maximize productivity are the multi-press head, which requires no re-tooling in cycle, the modulated dynamics of the manipulator with 9 independent pincers and the integrated shear, which works in Punch&Cut mode. These unique solutions also improve the flexibility of the S4.G4 as – whatever the geometries and materials being machined – they produce large batches, kits or batch one with equal ease.

The multi-press head, a distinctive feature of Salvagnini punching machines, requires no re-tooling or tool changes in-cycle, reducing overall processing times.

Salvagnini has always worked to produce solutions with low environmental impacts, guaranteeing maximum operator safety and resource optimization.

S4.G4 implements differentiating solutions that reduce consumption while guaranteeing the same performance and reliability, as they are based on successful applications borrowed from other product lines.

S4.G4 is equipped with advanced hybrid actuators: a proprietary solution used to reduce average consumption by up to 20% compared to the corresponding electrical solutions. This original solution has made it possible to eliminate mechanical parts, to the benefit of a structural simplification that eliminates maintenance due to worn moving parts in electrical actuators, and guarantees extremely stable performance and at 100% in stress tests. In addition, this solution does not require a cooling system, as there are no moving parts that could overheat, so further reducing consumption, today the lowest on the market for punching-shearing centers.

The head is extremely accessible for simple and agile tool change and extraction, meeting not only the user’s requests but also the ergonomic usage requirements set by the current standards.

The adaptive technologies, closed-chain controls, sensors and proprietary solutions assure that the materials are used in the best way, with zero waste by effectively reducing scrap.

The S4.G4 is a flow solution. In its basic configuration, it integrates feeding and unloading solutions that automate the production process and optimize each operation: at the infeed, a conveyor-centering device anticipates the loading of the sheet metal in masked time, positioning it correctly; at the outfeed, each part is automatically transferred to the next devices or the collection bins.

In addition to solutions that optimize the efficiency of each operation, Salvagnini supplies automation and process software which, by suitably organizing the whole production flow, help to achieve greater autonomy for unmanned and lights-out jobs, reducing the impact of labor costs and the return-on-investment time.

The S4.G4 is easy to configure and can work stand-alone, in-line, integrated into a flexible cell or for lights-out manufacturing.

- The loading/unloading solutions allow unmanned operations, enhancing the productivity of the punchingshearing center.

- The modularity of Salvagnini's automation devices allows the production flow to be extended and/or modified, even after first installation.

- In addition to integrated automation, Salvagnini supplies a wide range of automatic loading/unloading and sorting devices which, coupled with a store, increase system autonomy and efficiency. These devices mean that different materials and thicknesses are always available for just-in-time jobs, minimizing waiting times for sheet metal feeding and reducing the risk of error or damage to the material resulting from human intervention.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the punching machine. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Technical data

| Model | S4.G4-30 | S4.G4-40 |

| Maximum sheet dimensions (mm) | 3048 x 1650 | 4064 x 1650 |

| Maximum sheet diagonal (mm) | 3650 | 4655 |

| Minimum sheet dimensions (mm) | 600 x 400 | 600 x 400 |

| Maximum speed (m/min): | ||

| X axis | 132 | 132 |

| Y axis | 117 | 117 |

| Speed with both axes moving simultaneously (m/min) | 176 | 176 |

| Maximum acceleration (m/s2): | ||

| X axis | 30 | 30 |

| Y axis | 17 | 17 |

Punching | Shearing | |

| Technology | Operating head | Simultaneous or independent X- and Y-axis cutting |

| Maximum material thickness (mm) |

| |

| Aluminum, UTS 265 N/mm2 | 5.01 | 5.0 |

| Steel, UTS 410 N/mm2 | 4.01 | 3.5 |

| Stainless steel, UTS 610 N/mm2 | 4.01 | 2.0 |

| Minimum material thickness (mm) | 0.5 | 0.5 |

1 No multitool.